Corrosion resistance is a critical factor in the design and fabrication of various parts. To enhance corrosion resistance, diverse coating technologies have been utilized. These coatings establish a physical barrier between the underlying material and the corrosive environment. Popular coating technologies include coating, hot-dip galvanizing, electrostatic powder coating, and ceramic coatings.

Furthermore, specialized coatings such as polyurethane coatings offer superior durability against specific corrosive agents. The choice of an appropriate coating technology depends on various variables, including the substrate being coated, the intensity of the corrosive environment, and the desired lifespan.

Understanding Corrosion Mechanisms and Prevention Strategies

Corrosion, the gradual deterioration of materials due to electrochemical reactions with their environment, can have devastating consequences for infrastructure, manufacturing, and everyday objects. To effectively combat corrosion, a comprehensive understanding of its underlying mechanisms is essential. Corrosion typically involves an movement of electrons between the corroding material and its surroundings, leading to the generation of oxides, sulfides, or other compounds. Several factors contribute the corrosion process, including temperature, humidity, pH level, and the presence of corrosive substances like salts or acids.

Successful corrosion prevention strategies aim to disrupt these mechanisms and protect materials from deterioration. Common methods include applying protective coatings, using corrosion-resistant materials, implementing cathodic protection systems, and controlling the environment via measures such as ventilation and humidity regulation. Selecting the most suitable prevention strategy depends on factors like the specific material being protected, the severity of the corrosive environment, and cost considerations. By understanding the intricate nature of corrosion and employing appropriate preventive measures, we can significantly prolong the lifespan of structures and equipment, minimizing economic losses and ensuring safety.

Protective Coatings: A Barrier Against Environmental Degradation

Environmental factors can drastically degrade the integrity and performance of materials over time. To combat this degradation, resistant coatings are applied to create a barrier against the harsh elements. These coatings consistently shield surfaces from wear, improving their lifespan and maintaining functionality. The choice of coating depends on the individual needs of the application, considering factors such as exposure to UV radiation, temperature fluctuations, and chemical pressures. By selecting the appropriate protective coating, we can consistently mitigate environmental impact and enhance the performance and longevity of our materials.

Corrosion Control in Industrial Environments

Industrial conditions are rife with factors that can lead to corrosion. This occurrence can significantly impact the lifespan of equipment, leading to costly repairs. To mitigate these risks, comprehensive corrosion control strategies are essential. Comprehensive programs often comprise a combination of techniques, such as protective films, chemical treatments, and design optimization. Regular assessment is crucial to identify early signs of degradation and execute timely measures.

Moreover, maintaining a hygienic work environment and adopting proper maintenance procedures for materials can significantly limit the risk of corrosion.

Advanced Coating Materials for Extreme Conditions

In the realm of engineering, coatings play a crucial role plant-based yogurt in enhancing the performance and longevity of materials subjected to detrimental conditions. To address these challenges, researchers are constantly developing innovative coating materials with exceptional properties. These advanced coatings display remarkable resistance to corrosion, high temperatures, and other environmental factors that can impair conventional materials. From aerospace applications to industrial operations, these coatings are essential for achieving optimal performance in demanding environments.

The Science of Corrosion Inhibition

Corrosion inhibition is a essential field within materials science that focuses on mitigating the unwanted effects of corrosion. This complex process involves the application of various substances known as inhibitors to safeguard metallic surfaces from degradation.

Corrosion inhibition mechanisms are diverse and can be classified into different categories, including adsorption, passivation, and the formation of defensive films. The effectiveness of an inhibitor relies on a range of factors, such as the character of the metal, the corrosive environment, and the level of the inhibitor used.

Understanding the basic principles underlying corrosion inhibition is indispensable for developing successful strategies to combat this prevalent problem in various industries.

Shaun Weiss Then & Now!

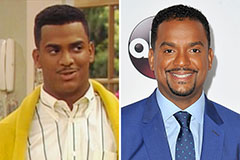

Shaun Weiss Then & Now! Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Judd Nelson Then & Now!

Judd Nelson Then & Now! Keshia Knight Pulliam Then & Now!

Keshia Knight Pulliam Then & Now! Ryan Phillippe Then & Now!

Ryan Phillippe Then & Now!